How to create a material in SAP?

- What is material creation in SAP

- Create Material in MM01

- Material Master views selection

- Basic data views

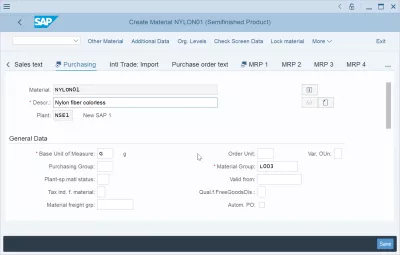

- Material Master Purchasing view

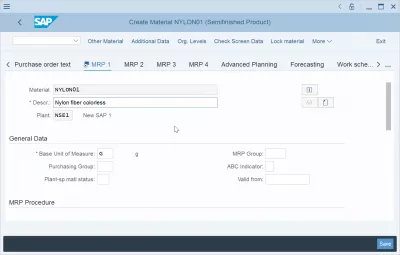

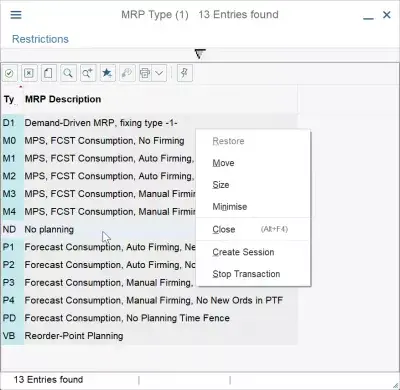

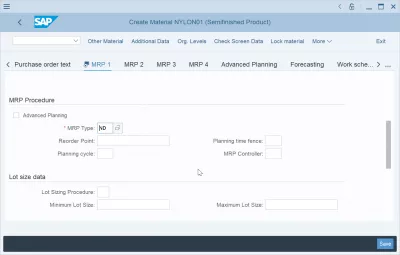

- Material Master MRP views

- Material Creation successful

- SAP Material Master tables

- Frequently Asked Questions

- S/4HANA SAP Materials Management Introduction video training - video

What is material creation in SAP

Creating a material in SAP can have two different definitions: either create a new material from scratch with transaction MM01, or extend an existing material to the required Material Master views with transaction MM02, such as Plant views to make the material available in another location or create a SAP purchase order, or Sales and Distribution views to be able to sell the product to other customers using the SAP system.

SAP Material Master tcode MM01 for creation, MM02 for extension, MM03 for displayIt is also possible to perform an SAP mass extend material to plant to extend at once a material to several organizations, using the MASS transaction code.

Extending a material to new organizational units in the SAP interface is also the way to solve common errors such as data not yet maintained for material:

- No sales and distribution data maintained for material, by extending Sales views in MM02 transaction,

- Accounting data not yet maintained for material, by extending accounting views in MM02 transaction,

- Material not maintained by purchasing SAP, by extending purchasing views in MM02 transaction.

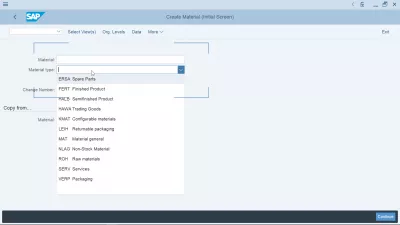

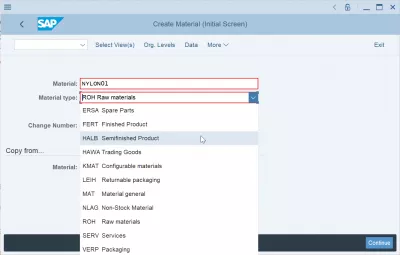

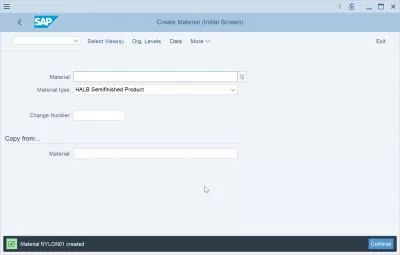

Create Material in MM01

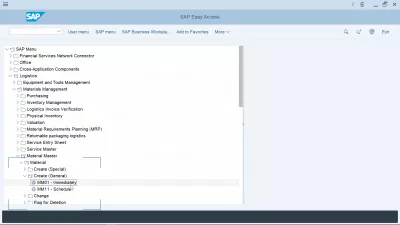

Start to create a material in SAP with the transaction MM01, create material.

The basic information to fill in are the material name, which is a unique identifier, and the material type, which can be either one of the standard material types, or a customized one:

- ERSA spare parts,

- FERT finished product,

- HALB semi-finished product,

- HAWA trading goods,

- KMAT configurable materials,

- LEIH returnable packaging,

- MAT material general,

- NLAG non-stock material,

- ROH raw material,

- SERV services,

- VERP packaging.

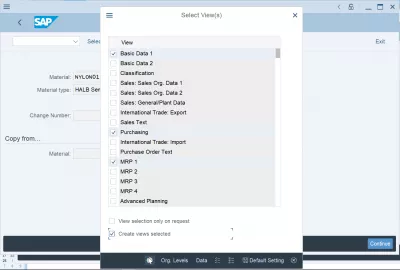

Material Master views selection

The next step will be to select which of the Material Master views will be opened for that material.

Selecting to open the SAP Material Master purchasing view will allow the material to be purchased, for example. Without that view opened, an error material not maintained by purchasing SAP would be generated when somebody will try to purchase this material, as it necessitates first to have corresponding information created in the SAP Material Master views.

Most important SAP Material Master views:

- Basic data, common data for the product within the whole organization,

- Classification, data used to material classification among each other,

- Sales: Sales Organization data, to be able to sell semi-finished or finished goods to customers,

- Purchasing, to be able to buy the product from suppliers,

- International trade, to be able to buy or sell the product in another country,

- MRP (Material Requirements Planning), to be able to plan material production.

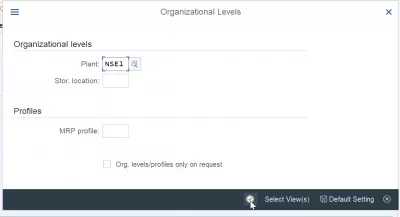

Once the views have been selected, it will be necessary to enter some organizational levels in which the material will be created.

Each SAP material master view uses its own organizational level, which will be used as table keys for internal storage. For example, the plant and material table in SAP, MARC, will store MRP views data in table MARC using material number and plant organizational unit as table key.

Meaning every material number can only be defined once per plant, but can be different for every plant.

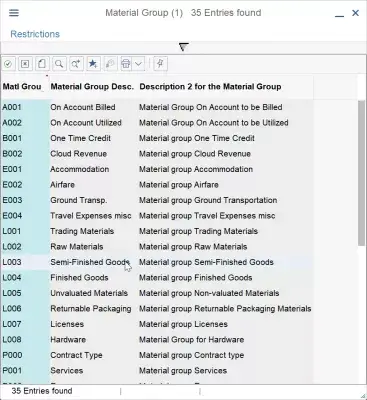

When creating a new material, it will also be necessary to enter a material group, which will be used to define which fields are available for the material. For example a raw material will have a weight unit, but a license material won't have any physical attributes as it is a digital asset.

Selecting the right material type is very important for the product lifecycle, as it will define how it can be used in the system and how it can interact with other modules and articles.

how to select views in material master change (MM02) - IT Tool BoxBasic data views

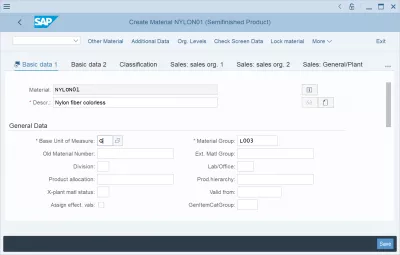

The first step in a new material creation will be to enter its basic attributes in basic data views: which unit of measure will be used for the material by default, which material group will define the article characteristics, and more.

Selecting the right material group will also decide which views can be opened for the material. For example, it could be decided that the company does not allow to buy finished goods for resell, and therefore the sales views cannot be opened for finished goods.

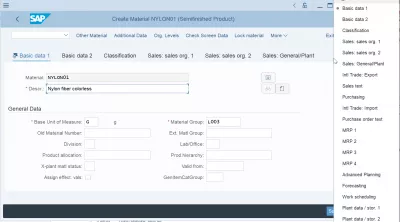

To navigate between all the views available for the material, simply click on the three dots button right above the fields view, on the right side of the screen.

A popup containing all available views will be displayed, and it will be possible to switch to any other view from there, providing that the mandatory fields in the current views have been properly filled in.

Material Master Data Views Material Master Basic - Course HeroMaterial Master Purchasing view

In the purchasing view, just like in every view from the material master, the corresponding basic data useful for the view will be displayed. They will change for every different view.

In each of these views, it will be possible to modify these basic information, which will then apply to the material in all organizations of the company.

Material Master MRP views

For example, in different views such as the material requirement planning SAP view, the basic data available will be different than the one in the purchasing view.

The extra fields specific to the view will also offer specific values. For example, the MRP type, which will define how the material requirements will be calculated for the production, can have one of several values by default: D1 for demand driven, ND for no planning, and more.

The information specific to the organization selected for the view will be displayed under different sub sections, such as MRP procedure section for the material requirement planning SAP data.

MRP views in Material Master - SlideShareMaterial Creation successful

Once all the views that have been selected for creation will have been properly filled in and validated with correct values, it will be possible to save the material and register its characteristics in the system.

By pressing enter key in the screens, it is possible to navigate through the screens, and to let the SAP interface take you to the next screen to verify - some fields don't need any value at all, as the standard values are usually enough.

Creating material master data in SAP - EASY SOFTWARE AGSAP Material Master tables

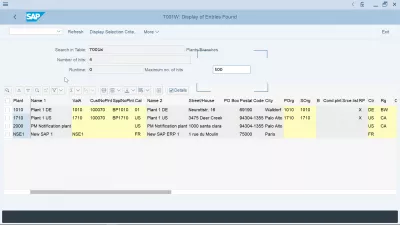

It might be useful to know where the data is stored in one of the many SAP Material Master table, for each type of data.

SAP Material Master tables:

- Material Master sales view table: MARA — General Material Data, VBAK — Sales Document: Header Data, VBAP — Sales Document: Item Data,

- Material class and characteristics table in SAP: INOB and AUSP, the SAP Material Master classification table cannot be accessed directly (see link to find SAP material class assignment table),

- SAP material plant table: MARC material plant table SAP,

- SAP Material Master accounting view table: MBEW,

- Table for plant and company code assignment in SAP: TCURM and T001W,

- SAP purchase group table: T024,

- Table for plant in SAP: T001W,

- Plant storage location table in SAP: T001L and MARD,

- SAP profit center tables: CEPC,

- Valuation class SAP table: T025 for classes and T025T for descriptions,

- SAP purchase requisition table: EBAN purchase requisition general data, EBKN purchase requisition account assignment data.

Most of these tables can be accessed using the table viewer SE16N transaction, and you can export to Excel from SAP using the SAP SE16 export to Excel option available under Export and then spreadsheet option.

Frequently Asked Questions

- What needs to be filled in when creating a material in SAP from transaction SAP MM01?

- The main information to be filled in is the name of the material, which is a unique identifier, and the type of material, which can be either one of the standard types of material, or individual (EPCA spare parts, FERT finished product, HALB semi-finished product, etc.).

- What are the methods for creating a material in SAP?

- Creating a material involves either using transaction MM01 for new materials or MM02 for extending existing ones.

S/4HANA SAP Materials Management Introduction video training

Yoann Bierling is a Web Publishing & Digital Consulting professional, making a global impact through expertise and innovation in technologies. Passionate about empowering individuals and organizations to thrive in the digital age, he is driven to deliver exceptional results and drive growth through educational content creation.